Who We Are

NEXCO-West USA, Inc. helps structural owners and engineering consultants obtain condition state data using non-destructive evaluation (NDE) and imaging technology. Our proprietary methods promote rapid and accurate data collection, and facilitate the generation of AASHTO element-based condition reporting.

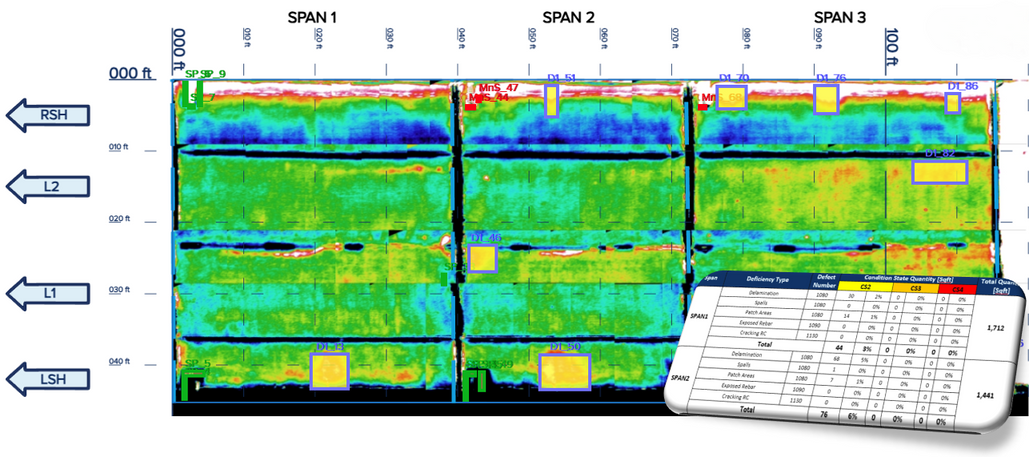

By imaging surface and sub-surface structural layers with high-definition visual, infrared thermography (IRT), and ground-penetrating radar (GPR) sensors, NEXCO maps deficient findings to help owners form a maintenance plan. With an extensive background in civil engineering, we call upon a wealth of expertise to perform our work.

Team

Masato Matsumoto, P.E.

President & C.E.O

Taizo Yamamoto

Vice President

Norie Ogata

Administration Manager

Kyle Ruske

Technology Leader

Hiroka Kimura, P.E.

Civil Engineer

Kaori Sacks

Researcher

Sean Hewitt

System Administrator

Xavier Cater

Visual Designer

Marlon Pacaji

Project Engineer

Rin Hashimoto, P.E.

Civil Engineer

Hideki Suzuki

Project Engineer

Aya Yoneda

Web Designer

Roberto Vivanco

Civil Engineer

Background

History

Non-destructive technology like IRT helps find unsound areas in structures that may not be visible to the naked eye. We use our impressive collection of sensors to take data in the field, analyze it, then summarize it in visual and numerical reports.

Our trained technicians can take imagery of an entire structure in a short period of time and generate several types of deliverable formats for review and comments. These reports will quantify the areas in need of repair and can offer specialized recommendations if requested.

We provide reliable results using our array of visual, IRT, and GPR systems while reducing the overall time and cost of inspection. Over the first decade of our company's establishment, we have garnered the support and high regards of transportation agencies, private owners, and academia alike.

Present

Commitment to Service

Current inspection practice exposes roadway workers to unsafe conditions. According to the Federal Highway Administration (FHWA), an average of 3 highway workers are killed each week on the job. This tragically high rate of fatalities can be improved by reducing the need for lane closures and long field time.

Our collection methodologies do not require direct, hands-on access to the target surface. Whether taken at a distance or from a mobile vehicle, they are designed to capture data that satisfy AASHTO, ASTM, NBIS, and NTIS standards while removing workers from prolonged periods at unsafe sites. This would lead to the reduction of lane closures on bridge decks, rappelling down tall building facades, and inconvenient shutdowns of tunnel systems.

Our conviction to safety is channeled into everything we do: from our everyday inspection work, to our transportation research. We never stop re-evaluating, improving, and fully utilizing our capabilities to couple efficiency with safety.

Future

Strategic Thinking

A large amount of bridges, tunnels, buildings, and other structures built during periods of rapid economic growth are reaching mature stages in their life cycles, leading to an overflow of safety inspections. The inefficiency of conventional inspection methods like visual confirmation, sounding techniques, and sketching are not keeping up with the needs of structural owners.

We offer an inspection framework powered by NDE data collection in the field and online report generation back in the office. With informed planning and careful consideration to life-cycle projection, we can combat the demand for high-quality and high-quantity inspections.

Partnering with the best minds in the imaging field and utilizing our robust resources, we develop service, hardware, and software solutions that reinvent the inspection process. Learn more about the technology which we strive to make a world-wide standard.